CRCA HIGH CARBON STEEL STRIPS

High carbon steels contain from 0.80 to 1.25% C with manganese ranging from 0.5% to 0.9% This steels are commonly known as spring steel. These steels are generally operated at very high stresses and heat-treated to obtain the maximum elastic limits and fatigue resistance without becoming sufficiently brittle to cause sudden failure in service. Hardenability of spring steel is very important because only fully hardened springs have the maximum resistance to take a permanent set (sagging).

We offer the following Grades :-

Chemical Composition |

||||||||

| Grade | %C | %Si | %Mn | %S | %P | %Cr | ||

| C-80 | 0.75 - 0.85 | 0.10.- 0.35 | 0.50 - 0.80 | 0.05 max | 0.05 max | - | ||

| C-98 | 0.90 - 1.05 | 0.10.- 0.35 | 0.50 - 0.80 | 0.05 max | 0.05 max | - | ||

| C125/HC21/125CR1 | 1.10-1.30 | 0.10.-0.25 | 0.30-0.60 | 0.05 max | 0.05 max | - | ||

Range |

|

| Width: | 8 mm to 500 mm (in thickness lower than 0.6 mm, 4 mm wide material can be supplied) |

| Thickness: | 0.07 mm to 5.00 mm |

| Hardness: | Fully annealed material with a maximum hardness of 200 VPN & special temper material with hardness ranging from 230 VPN to 270 VPN. |

| Surface Finish: | Bright |

Form of supply:Materials are supplied in coil form. If any special I.D. & O.D. requirements are there, that can be maintained. Further, material can also be supplied in cut lengths, if required by the customer.

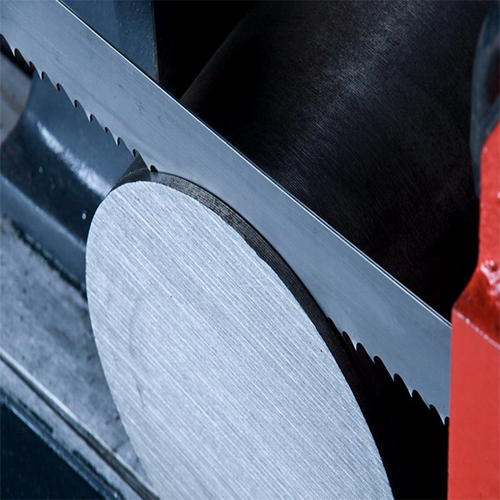

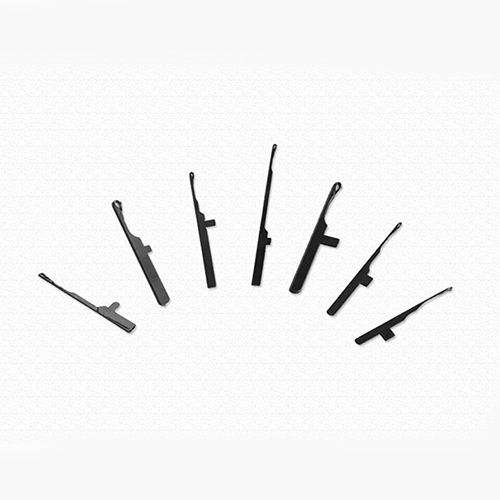

Applications: Surgical Blade(Scalpel), Metal Cutting Band Saw Blades, Circlips, Textile Needles, Automobile Components, Knives for Cutting Foam & Plastics, Agricultural Tools, Hack Saw Blades .etc.